ABC is a more sophisticated method that allocates overhead costs to products based on the activities that consume those costs. ABC can be more accurate than traditional overhead allocation methods, but it is also more complex and time-consuming to implement. In contrast, direct labor and manufacturing overhead costs are assigned to products to analyze actual labor hours and machine time used.

Variable costs are costs that change in proportion to the level of production or activity. First, it helps businesses to accurately calculate the cost of goods sold and to set prices for their products. Overhead costs can be fixed, variable, or semi-variable, depending on how they change with production levels. Because these expenditures cannot be directly tied to the production of goods, reducing them can be difficult if the location of your business does not offer competitive pricing for space and services.

How to calculate manufacturing overhead [Formula + examples]

Indirect costs cannot be directly attributed to one specific product or service. The most common types of indirect costs include rent, utilities, insurance, and administrative services. When determining manufacturing overhead, you must consider all direct and indirect labor related to the production of the particular item in question. Therefore, manufacturing overhead can be an expense when calculating the cost of goods sold. Manufacturing overhead (also known as factory overhead, factory burden, production overhead) involves a company’s manufacturing operations. It includes the costs incurred in the manufacturing facilities other than the costs of direct materials and direct labor.

The inventory of a manufacturer should report the cost of its raw materials, work-in-process, and finished goods. The cost of inventory should include all costs necessary to acquire the items and to get them ready for sale. Therefore, one of the crucial tasks for your accountant is to allocate manufacturing overheads to each of the products manufactured. As the name suggests, the semi-variable costs are the expenses that are partially fixed and partially variable. In other words, such expenses would increase if the output goes beyond such a level. Fixed Overheads are the costs that remain unchanged with the change in the level of output.

Manufacturing Overhead (Explanation Part

Once you understand the various types of overhead, you’re ready to calculate business overhead costs. One of the most important things to remember when calculating overhead is to not include any direct expenses, such as products and materials purchased that are used for resale, or direct labor. Indirect labor is the cost to the company for employees who aren’t directly involved in the production of the product.

Furthermore, this will remain constant within the production potential of your business. Accordingly, the overhead costs can be classified into fixed, variable, and semi-variable costs. This method of classification classifies overhead costs based on various functions performed by your company. Apart from advertising, overhead costs also include production overheads, manufacturing overhead costs include administration, selling, and distribution overheads. Now, you incur certain costs that can be directly traced to the production of a specific good or service. You can also choose to use machine hours rather than labor hours when calculating your overhead allocation, replacing the number of labor hours with the number of machine hours in your calculation.

How ProjectManager Helps with Manufacturing Costs

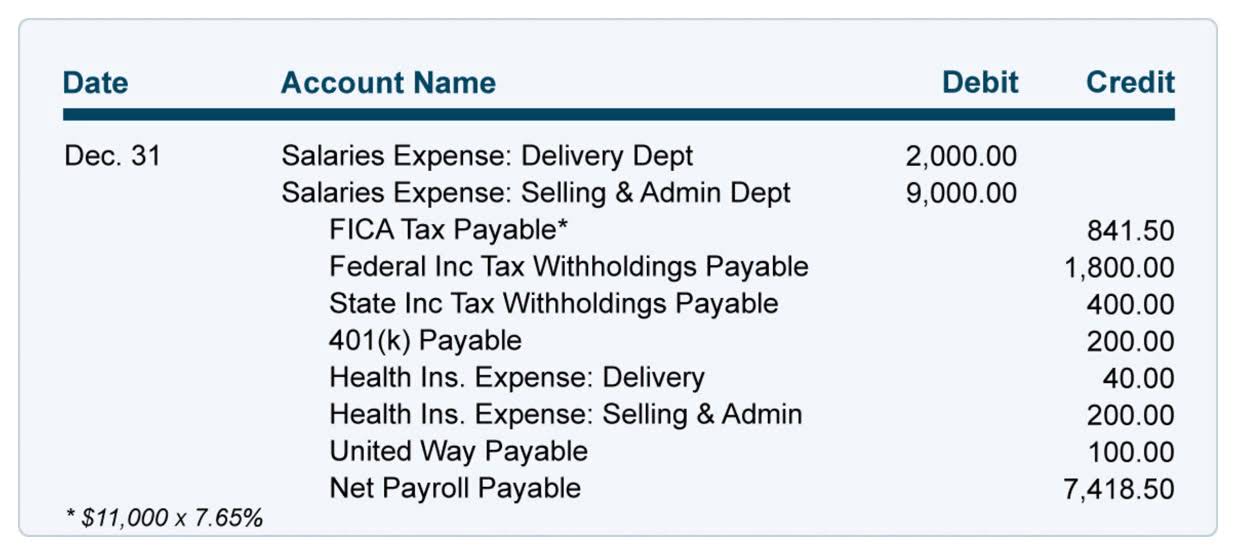

Activity-based costing (ABC) is a costing method that assigns overhead costs to products and services based on the activities that consume those costs. Manufacturers can use different methods to allocate manufacturing overhead costs to products. This rate is calculated by dividing the total manufacturing overhead costs by the total number of units produced. The overhead rate is then multiplied by the number of units produced to determine the amount of manufacturing overhead that is allocated to each unit. Manufacturing overhead are also called factory overheads or indirect manufacturing costs. These costs are indirect in that it is impractical to directly trace them to each product.

For example, if you have high overhead, you can take the necessary steps to reduce it. If your overhead in business is low, it may be a good time to consider adding an additional product to your current line. In May, you produced and sold $10,000 worth of frames, but broken equipment in June decreased output, so you only manufactured and sold $2,000 worth of frames.